Watered Down

Aerospace Components Water Pump keeps its cool when the competition heats up

By Michael Galimi

Right now—as I type this story—it is hot outside. The heat index is pegged at 101-degrees with the humidity and air temperature combined. For many racers across the country triple digit heat is a part of life during certain times of the year. Even in milder conditions, a properly operating cooling system will keep your engine running smoothly and consistently as water circulates through the engine, staving off hot-spots in the cylinder heads and block.

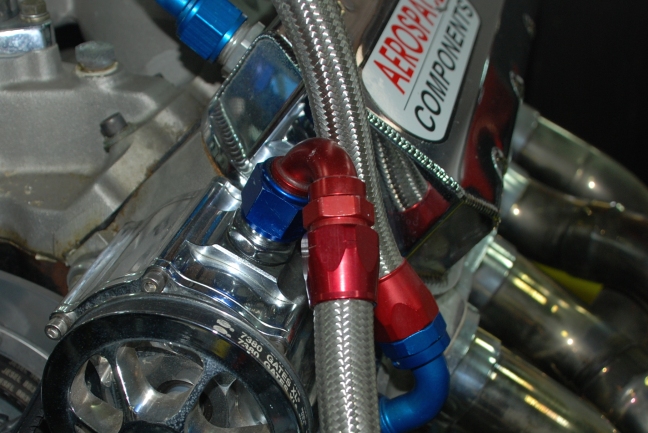

An integral part to the cooling system is the water pump and practically a standard in drag racing is an electric motor to turn the pump. Without a water pump the coolant (water in drag racing applications) couldn’t circulate through the engine, into the radiator to get cooled off, and back into the engine to soak in more heat. Aerospace Components has tapped into its engineering and manufacturing prowess to deliver a durable and high-functioning electric water pump.

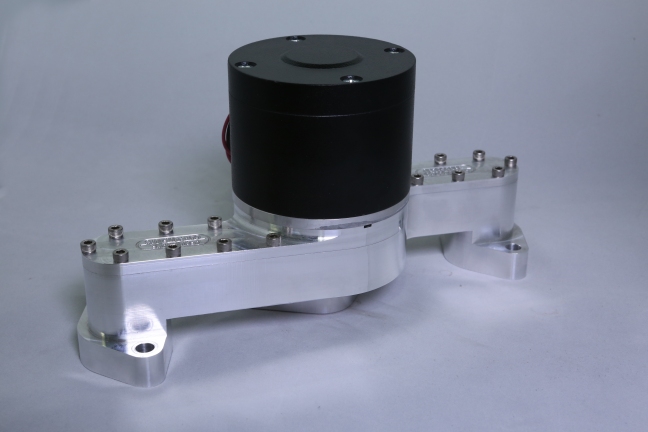

Aerospace Components took great care in adding an electric motor that was durable and powerful but also offers a low amp draw (4 amps).

“We all know how hot it has been this summer and the pump [ed note—Aerospace Components Water Pump] is meeting those demands; it performs as good as it looks,” said noted NMCA racer Dave Theisen who competes in the competitive heads-up category of NA 10.5. His 1969 Pontiac Firebird is powered by a 611ci big-block Chevy that routinely pushes Theisen into the high 7s at nearly 175 mph.

The current line-up of Aerospace Components water pumps covers big-block Chevy, small-block Chevy, small-block Ford, the 4.6L and 5.4L Ford Modular engine families, and a universal kit. Each water pump retails in the low $400 dollar range, keeping it affordable given its exceptional capabilities, quality, and it pays back to NMRA, NMCA, and NMCA WEST racers in the form of contingency cash rewards for the winner and runner-up finishers.

The water pump is designed to clear most belt-drive systems on big-block and small-block Chevy and small-block Ford applications.

Aerospace Components Water Pumps, regardless of the application, are capable of flowing 37 gallons per hour (gph) in most applications. Obviously the line size, 12- or 16-volt electrical system, and any water restrictions will have an effect on the flow rate. The water flow pushed by the pump is sufficient to keep the engine cool during longer drive cycles and in higher horsepower applications that have high-compression or a power adder; both are contributors to higher cylinder pressures leading to greater heat production from the engine.

The electric motor that Aerospace Components includes on all of its water pump kits has a very low amperage draw of just 4 amps. Limiting the amp draw of components means it lessens the tax on the electrical system, leaving plenty of juice for other systems like throttle stops, delay boxes, massive electric fuel pumps, lights, etc. And lest you think that the low amp draw comes at the cost of the motor’s capabilities, the Aerospace Components water pump motor moves 37 gph and is rated for continuous duty.

Like so many other Aerospace Components, Al Kussy incorporated a lot of 6061 T6 billet aluminum into the water pump’s design. Every water pump setup, from its universal pump to the big-block Chevy kit, includes a 6061 T6 billet aluminum housing and impeller. Additionally, a high-performance shaft seal is utilized for longevity and durability in the harsh racing environments. Aerospace Components also includes stainless steel hardware in all of its kits.

In typical Aerospace Components fashion, high-quality 6061 T6 billet aluminum is standard in many aspects of the race part. All Aerospace Components products are Made in the U.S.A.

For those who require a remote mounted water pump or repurposing it for use in an air-to-water intercooler system, the company sells a universal kit. It has a single one-inch NPT inlet and two ¾-inch NPT outlets. For the big-block and small-block Chevy and Ford applications, Aerospace Components gives the buyer a choice for the inlet fitting size and each one of those kits clears most aftermarket camshaft belt-drive systems. NMCA West racer Ricky Deuschle said it best when he described the water pump and his other Aerospace Components products, “Boy, what a product!” He went on to tell us that as a career machinist, he is very impressed with the quality as well as the performance of all the Aerospace Components parts he runs on the family’s racecars.

How does it work in the real world? Deuschle offered a story about his recent outing at the Auto Club Speedway, which is located in Fontana, CA. The Deuschle family runs three Top Sportsman racecars and a 1969 Camaro Z/28 in Super Gas, each vehicle is equipped with virtually the entire Aerospace Components catalog of parts. This particular race weekend saw 100-degree weather in Southern California. Any experienced bracket racer knows that as elimination day wears on, the time between rounds diminishes. With just 20 minutes to cool down and prepare the cars, Deuschle said his car and his sisters’ rides were all pushing their water temperature needles to 200 degrees or more. A quick flip of a switch activated the water pump for each car and within 15 minutes the temperature dropped to a more acceptable 130 degrees. The quick cool down allowed the cars to perform without the risk of popping a head gasket or another failure from high water temperature.

The water pump might not be the latest go-fast goody like a new supercharger or a set of cylinder heads, but in the heat of racing, particularly in the summer months, keeping the engine ready for action is vital to success. That includes maintaining reasonable water temperatures through the burnout and during a pass down the quarter-mile. Additionally, running the electric pump in the pits keeps water circulating to cool down the engine before the next round of eliminations.